1. Overview

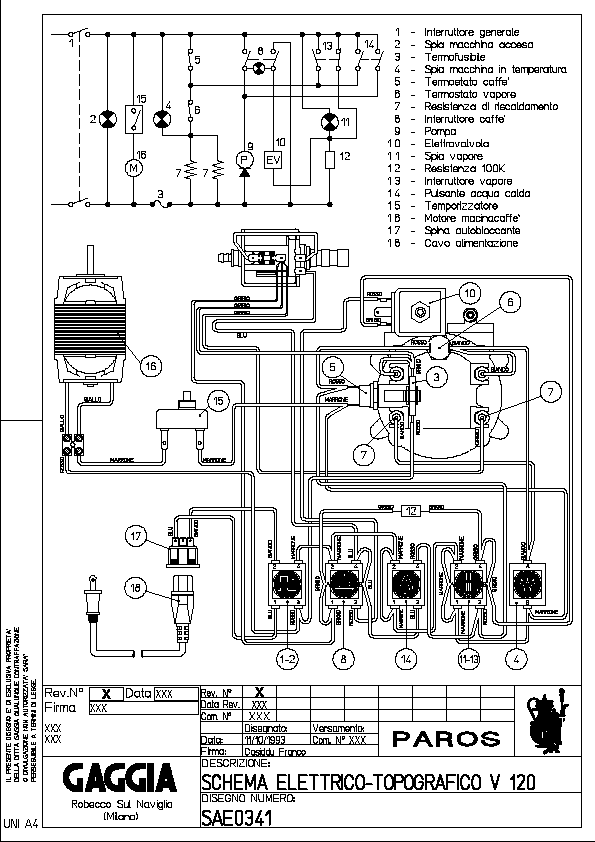

This is the electric diagram of the Gaggia Paros:

Gaggia Paros electrical wiring

The switches 5 and 6 represent the two thermostats that are going to be replaced

with two temperature sensors and a Solid State Relay that the Arduino will

use to control the heater.

The second required modification is to connect the Arduino to the left pins of the

“double switch” number 13. This will allow the Arduino to know if the Steam button

has been pressed in order to target the correct temperature.

This is the list of materials I used for this project. The purpose here is to just give an idea of what I used, you can change anything as you might prefer:

- Temperature sensors (x2). I tried with both:

TSic 306 digital temperature sensor

K-type thermocouple with a MAX6675 ADC module

128x64 OLED with SSD1306 controller

Arduino Nano

Arduino Nano expansion connection shield

Fotek clone SSR 40A

Wires 22AWG (low voltage) and 18AWG (AC line)

Heat shrinking sleeves

T-tap (scotch) connectors

Thermal paste

M4 brass hexagonal standoff

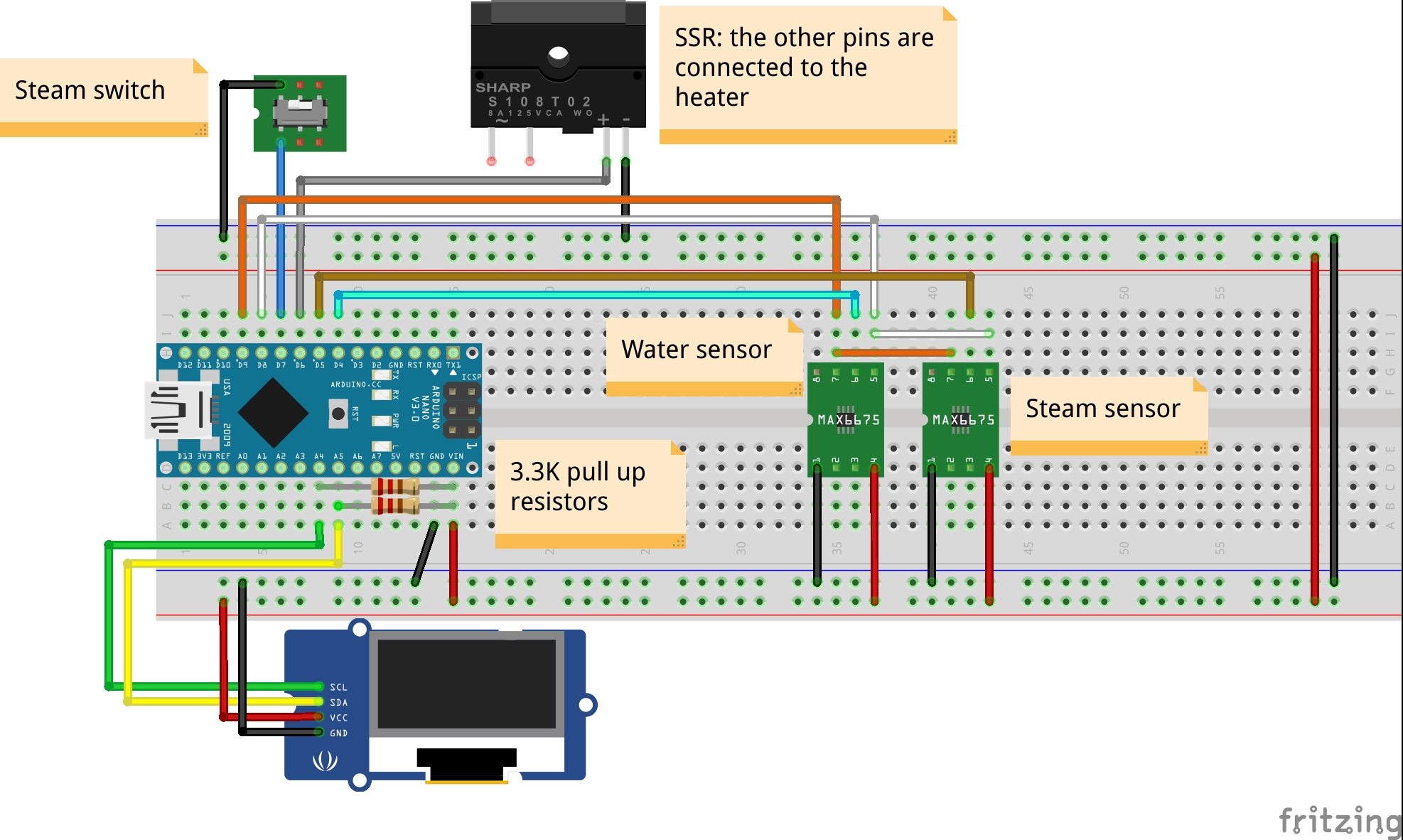

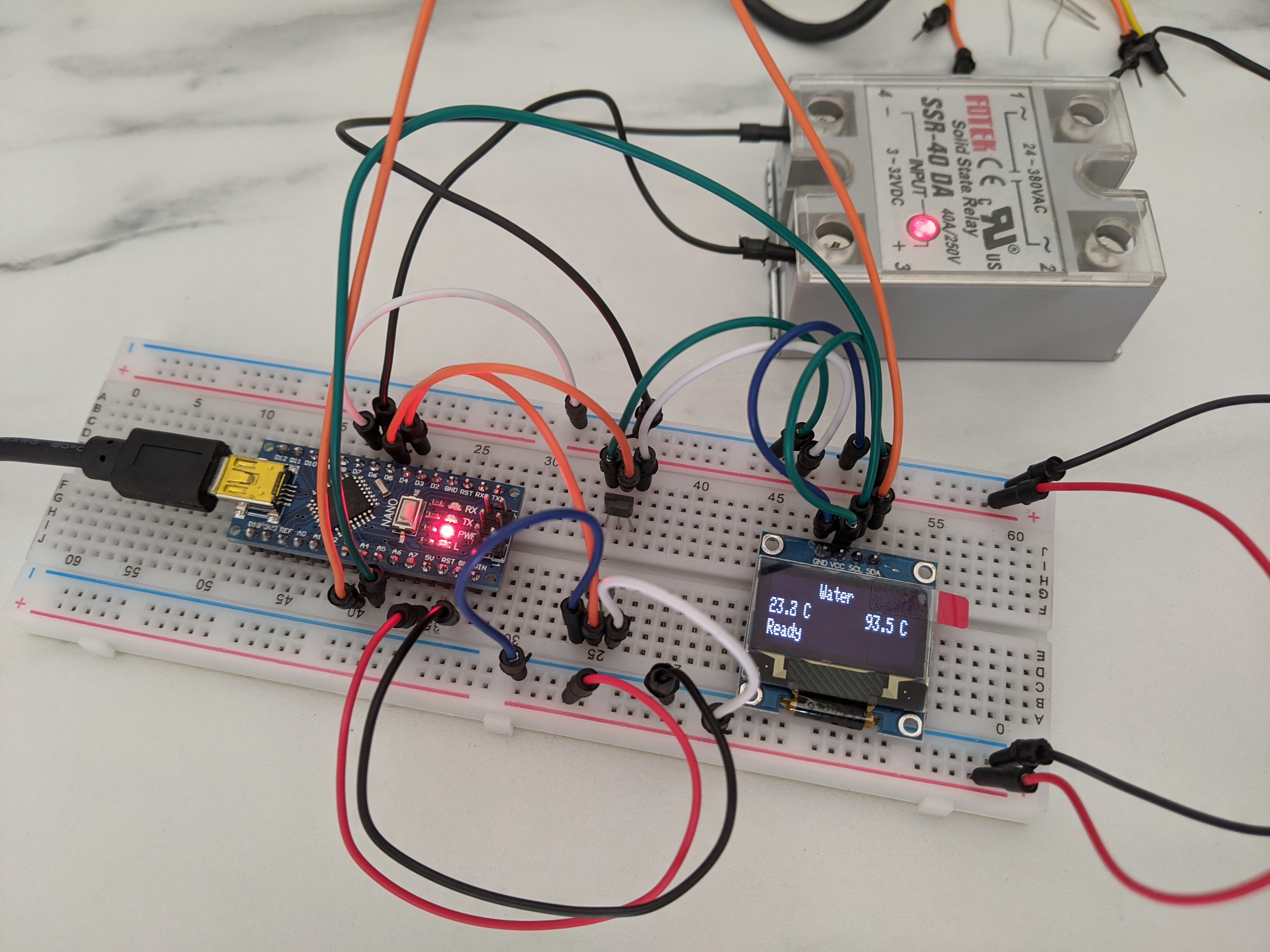

This is the diagram of all the components connected for testing on a breadboard. In the diagram the thermocouple sensors are missing and their pins are to be considered as connected to the two MAX6675 modules. The same exception is true for the SSR AC pins.

Breadboard circuit diagram

2. Arduino

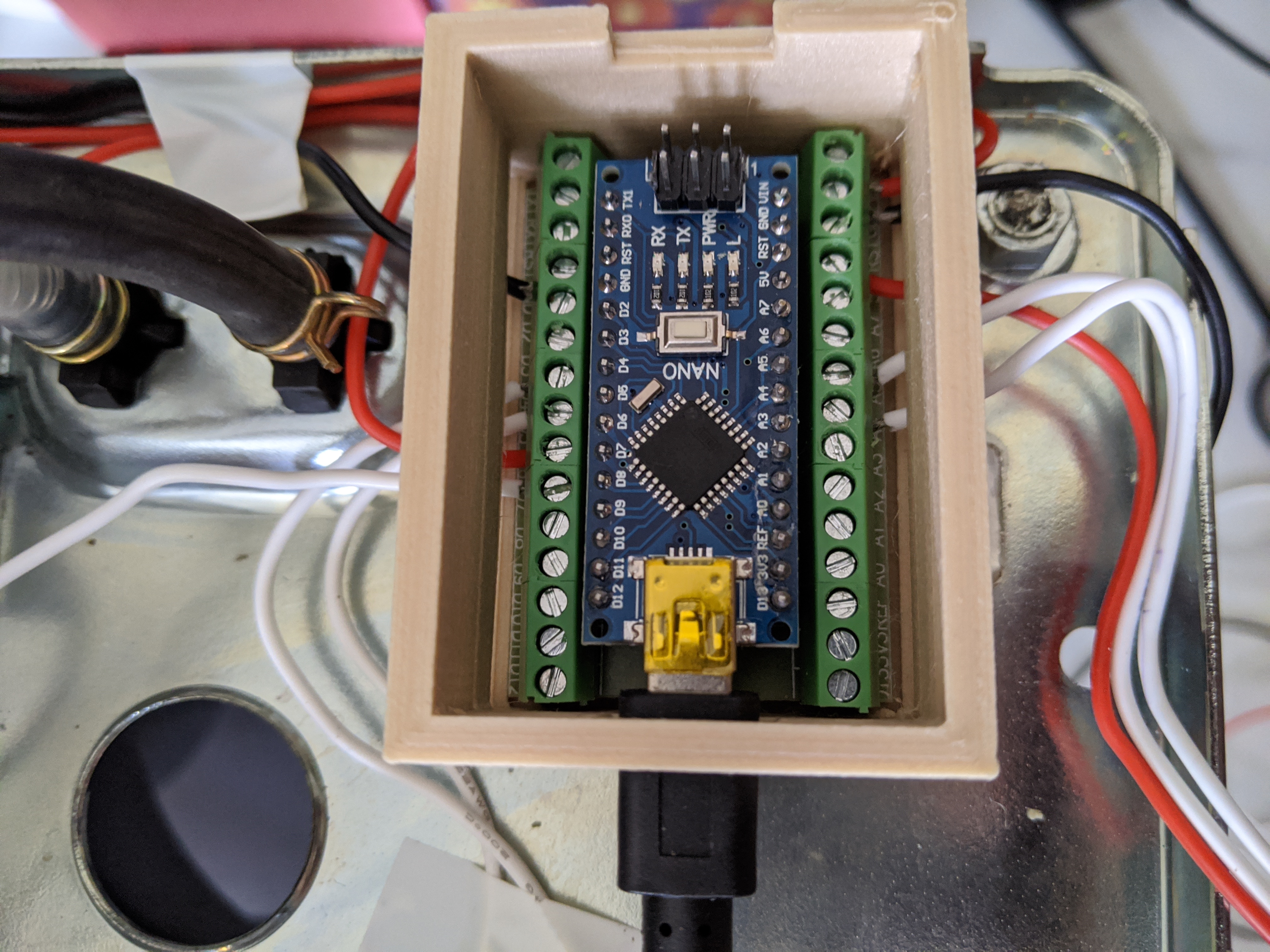

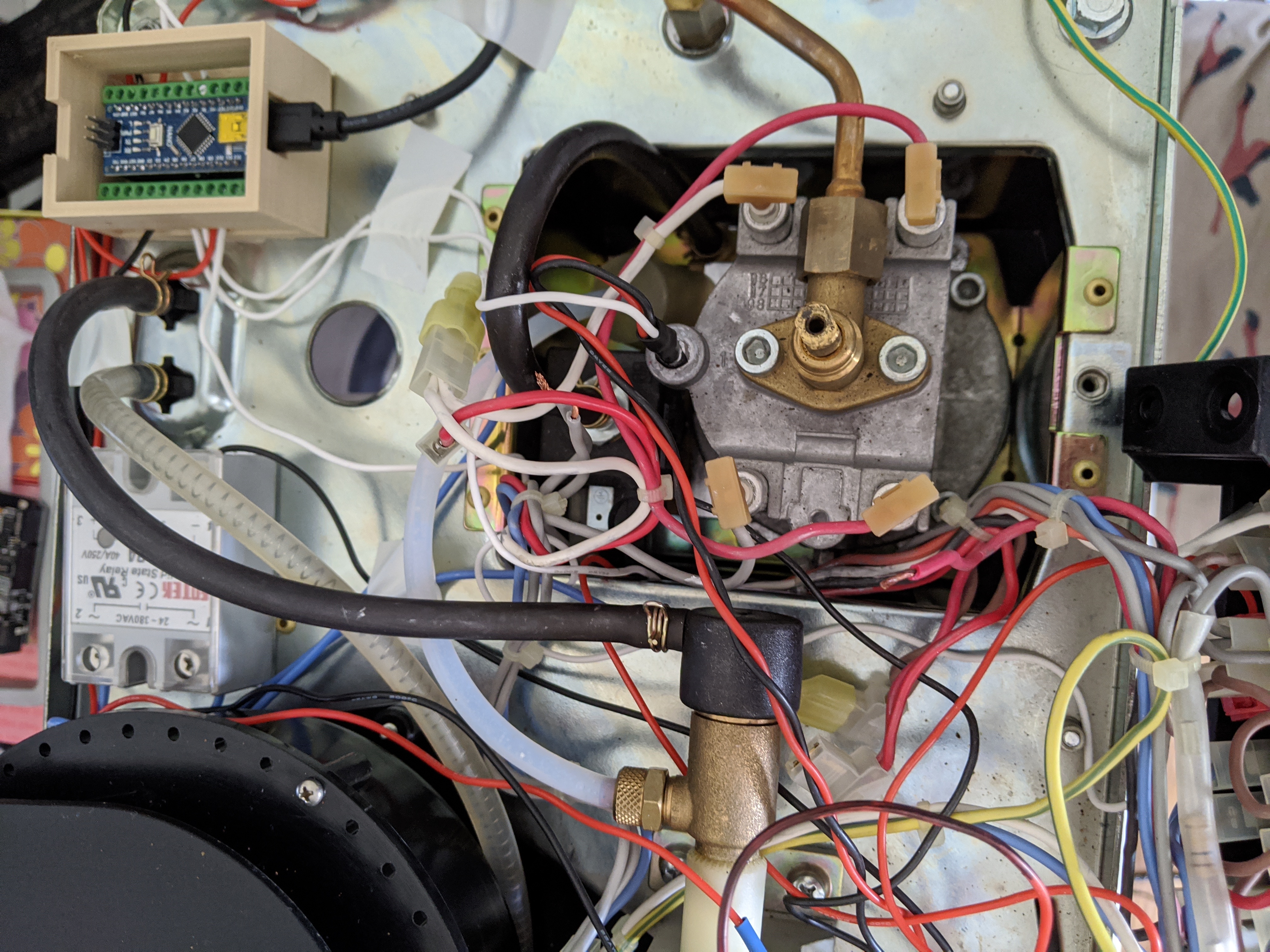

I decided to use an Arduino Nano because of its small size and the USB port which is handy to upload sketches and interface with the Serial for debugging. I decided to not use a PCB as most of the components are far from each other and I wanted to allow easy plug and play of each module. I then connected the Arduino Nano to an expansion board that allows to connect wires with screw connectors without having to solder anything. I 3D printed a simple box to contain and isolate the Arduino from the machine frame.

Arduino Nano and its expansion board

3. Temperature sensors

I have tested this whole setup with two different types of sensors:

TSic306

K-type thermocouple

3.1. TSic306

At first I decided to use the TSic 306 digital temperature sensors. As suggested in similar projects there are several benefits: it’s digital so no need for ADC or external bridge boards, max operational temperature is +150deg C which is ok as the steam needs to get around 145deg C and it comes in a TO92 package which is quite compact.

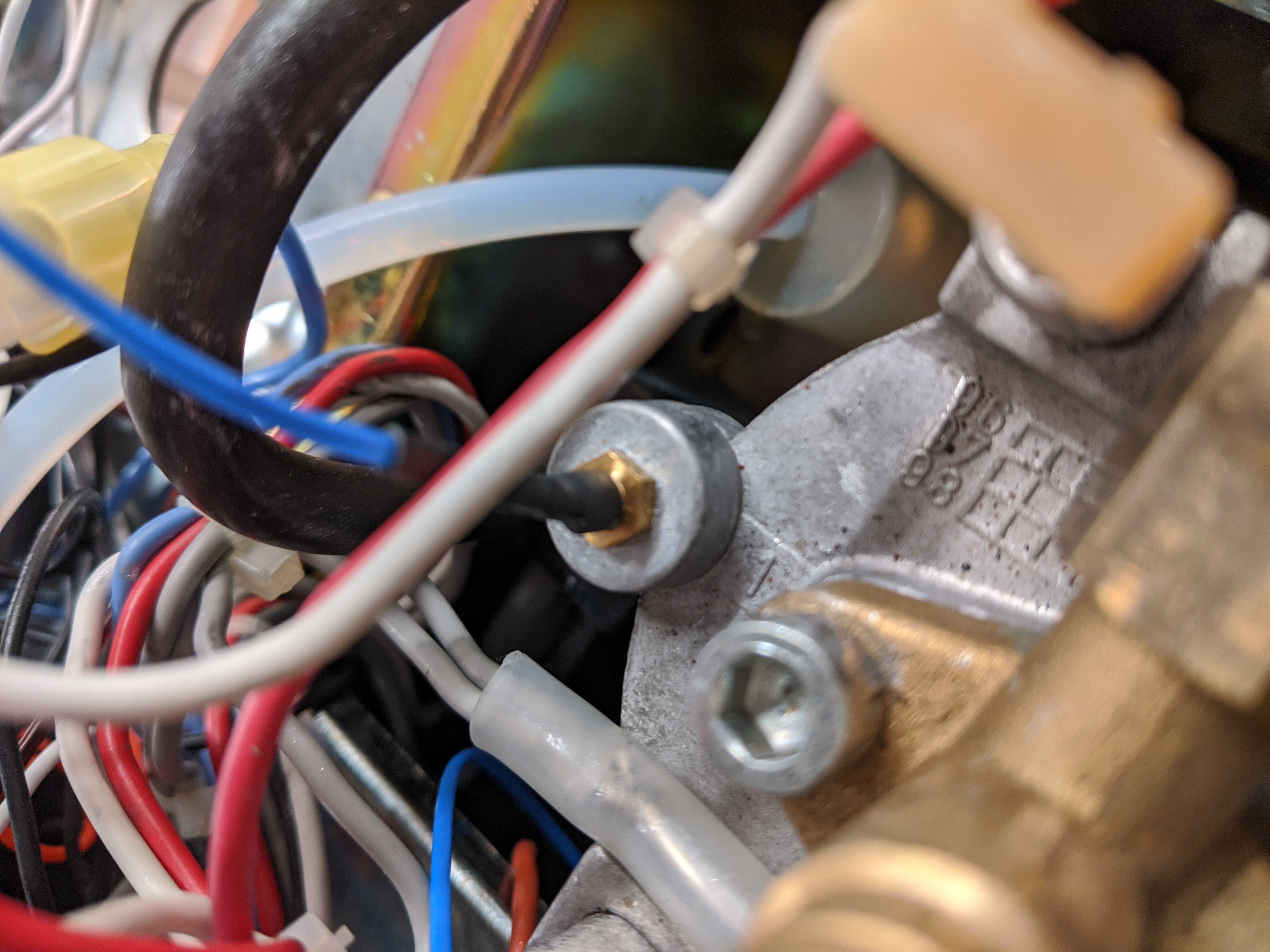

The main challenge I had with these sensors was fitting them in the heater: the stock thermostats are connected through a M4 screw, so following advice from other similar projects I bought a couple of brass hexagonal standoff with a M4 male thread and I tried to find a way to assemply the sensors into them.

Unfortunately the TO92 package is 4.5mm wide so I used some sand paper to smooth the corners of the sensors, trying to not damage the internal wirings. Ideally I would have drilled the M4 female thread but I did not have a drill at hand :(

I then filled the female thread with thermal paste and I inserted the sensors in the paste. Eventually I covered everything with a heat shrinking sleeve.

Temperature sensor TSic306 assembled

This setup worked very well for several months until I had to do some maintenance to the machine: removing the heater to replace the solenoid valve I broke one of them. The problem with this solution was that the two sensors were not really stable in the brass standoff and it was easy to knock them off by touching them or pulling the wires.

3.2. K-type thermocouple

I then decided to try out two K-type thermocouples. I bought two of those that come already assembled on an M4 nut (designed for 3D printers) which is handy as this was the weak point of the previous solution.

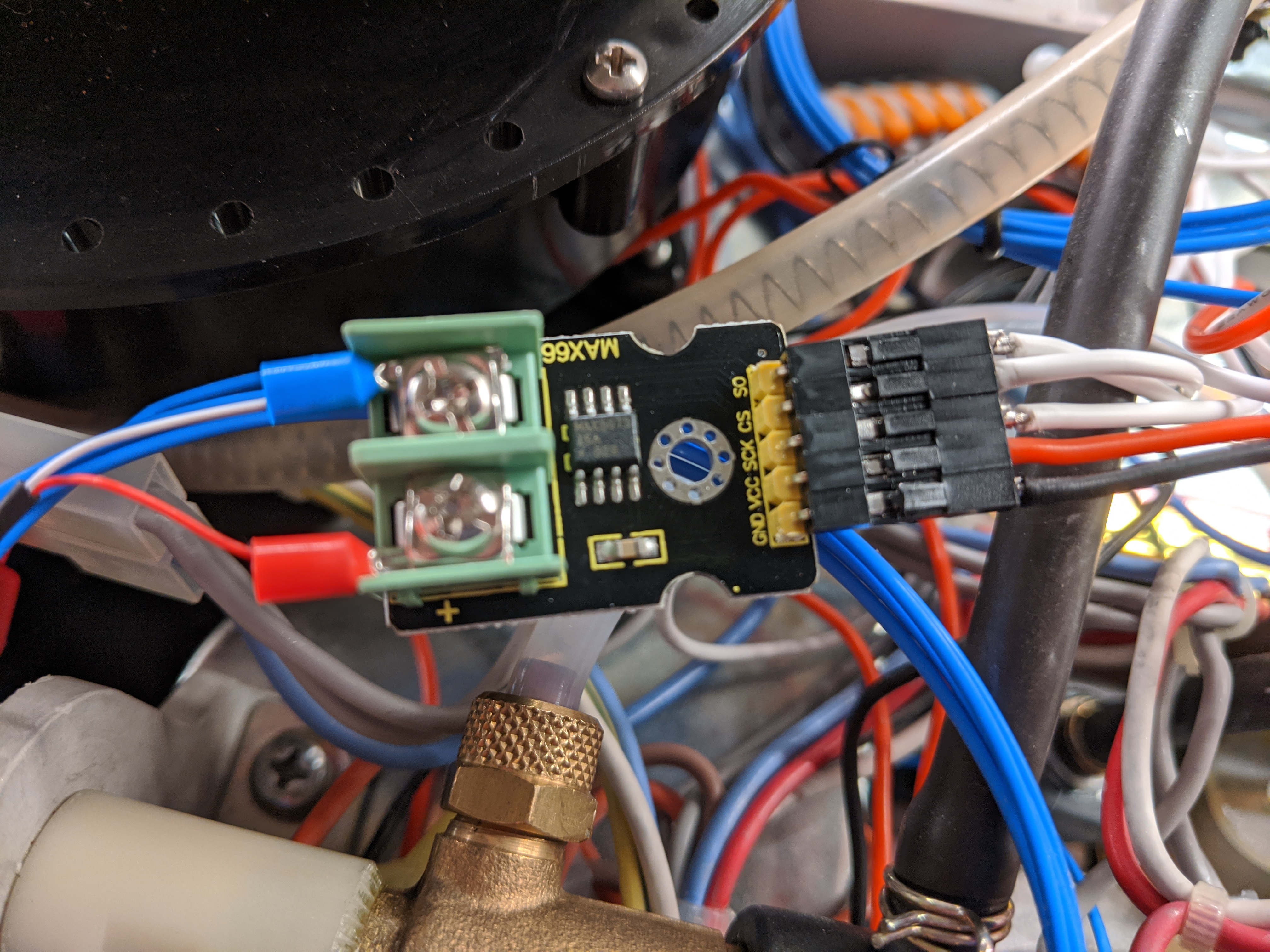

The main drawback is that they require a voltage amplifier and an ADC to digitalise the signal. Fortunately both of these can be sourced in a single package, the MAX6675 module. The Arduino can “speak” with the MAX6675 with the SPI protocol requiring 2 more pins compared to the digital sensor solution. Not a big deal as there are plenty available.

K-type thermocouples assembled on the heater

MAX6675 module

Another possible drawback with thermocouple is the error they might be subject to: again I was not really worried about this because even if there is a ~2deg C error, as long as it’s stable (basically just an offset) it would not impact the PID performances.

4. Solid State Relay

I used one of the common (and cheap) Fotek clone SSR. From what I could read online these clones usually contain underrated triac, so to stay on the safe side I used the 40A version with the hope it’s not going to blow up. This type of SSR can be controlled with a signal in the range 3-32 VDC and they update the output when the AC signal crosses its zero level.

The SSR can be placed inside the coffee machine with it’s metal back side on the coffee

machine metal frame in order to dissipate any heat. The control signals are going to be

wired to the Arduino board: one to GND and one to the selected digital pin.

Arduino Nano and the Fotek SSR

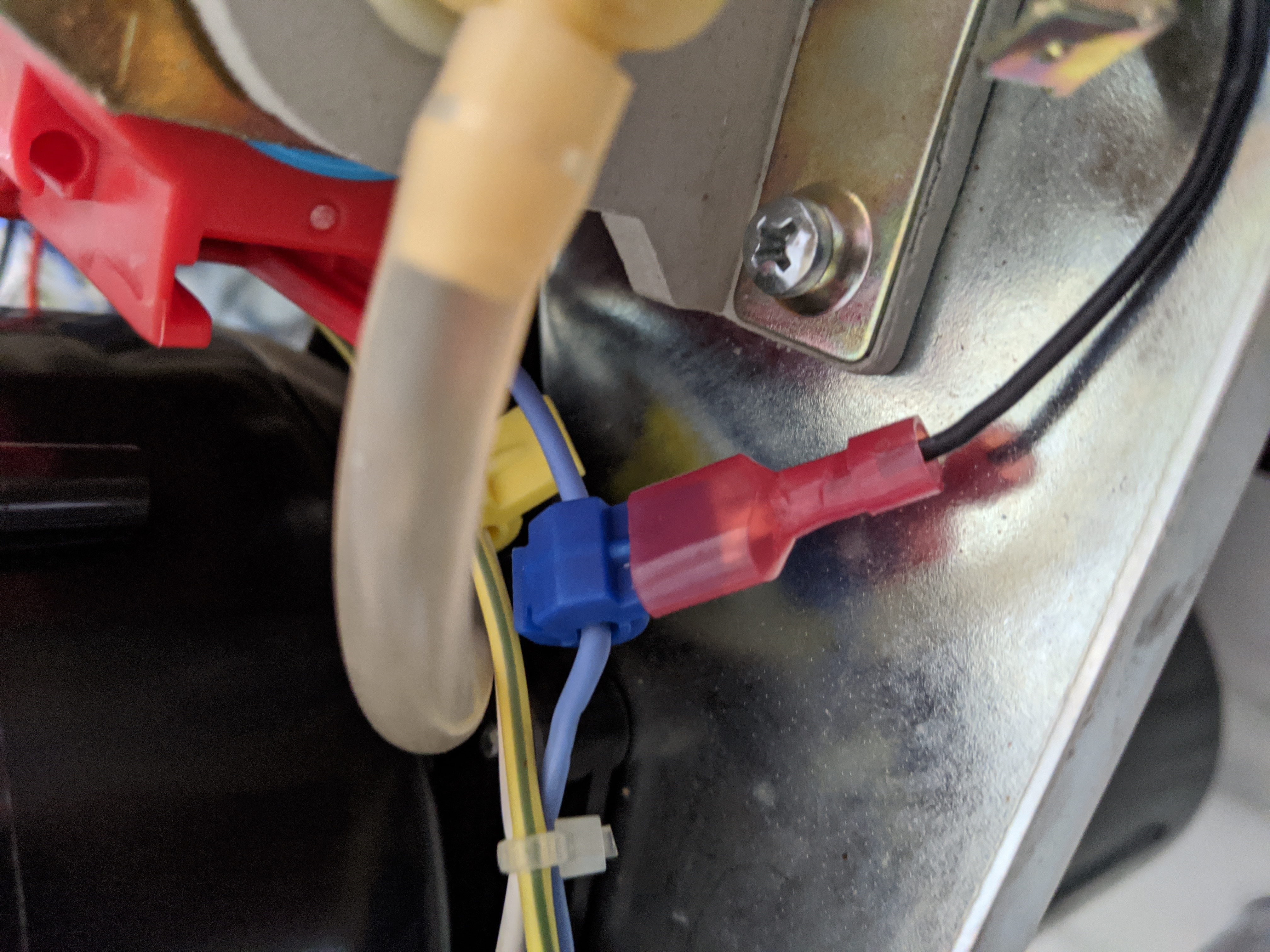

The AC terminals instead needs to be connected to replace the two thermostats. One

themostat is connected to a red and a brown wire, while the second one is

connected to a white and again a red wire. I connected the SSR terminals using

a piece of 18AWG wire and 2 male spade connectors, one to the brown connector

of the first thermostat and the second one to the white connector of the other

thermostat.

Connection between SSR and the heater

5. Power supply

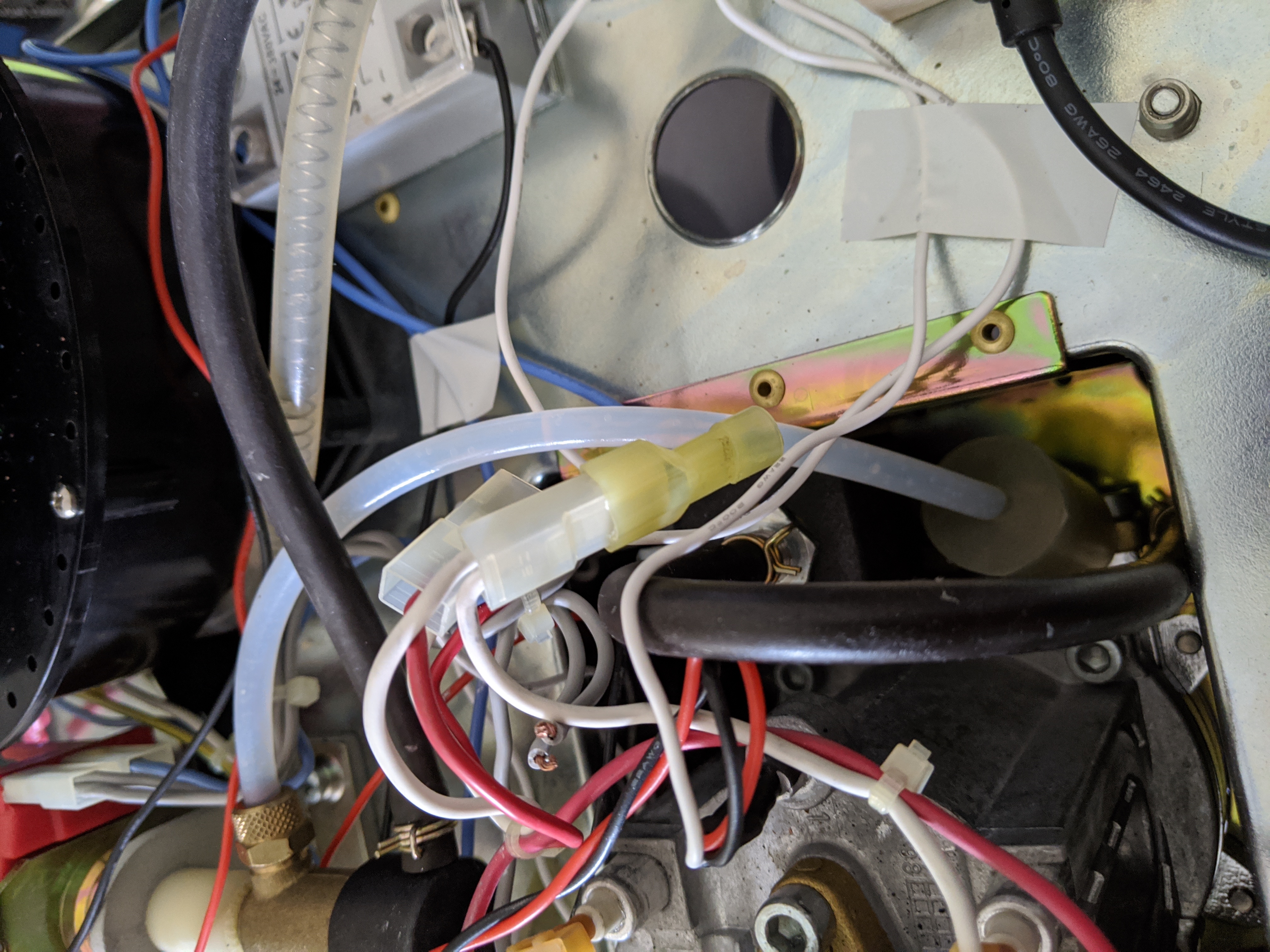

There might be different ways to power the “low voltage” electronic for this project, at first I thought to use AAA batteries as the overall consumption is very low and the whole circuit is on only for 30min a day in average. Eventually I decided to take power from the main AC source using T-Tap connectors and use an AC-DC switch converter (cheap from Ebay).

TTap connector on AC power line

Using the T-Tap connectors allowed me to not having to cut or solder almost anything, and everything can still be removed reverting the machine back to it’s original state.

Eventually I enclosed the whole circuit board in 3D printed plastic case leaving it inside the coffee machine, as far as possible from any other components. The 5V lines has been wired to reach the Arduino board and the temperature sensors.

Power supply enclosure

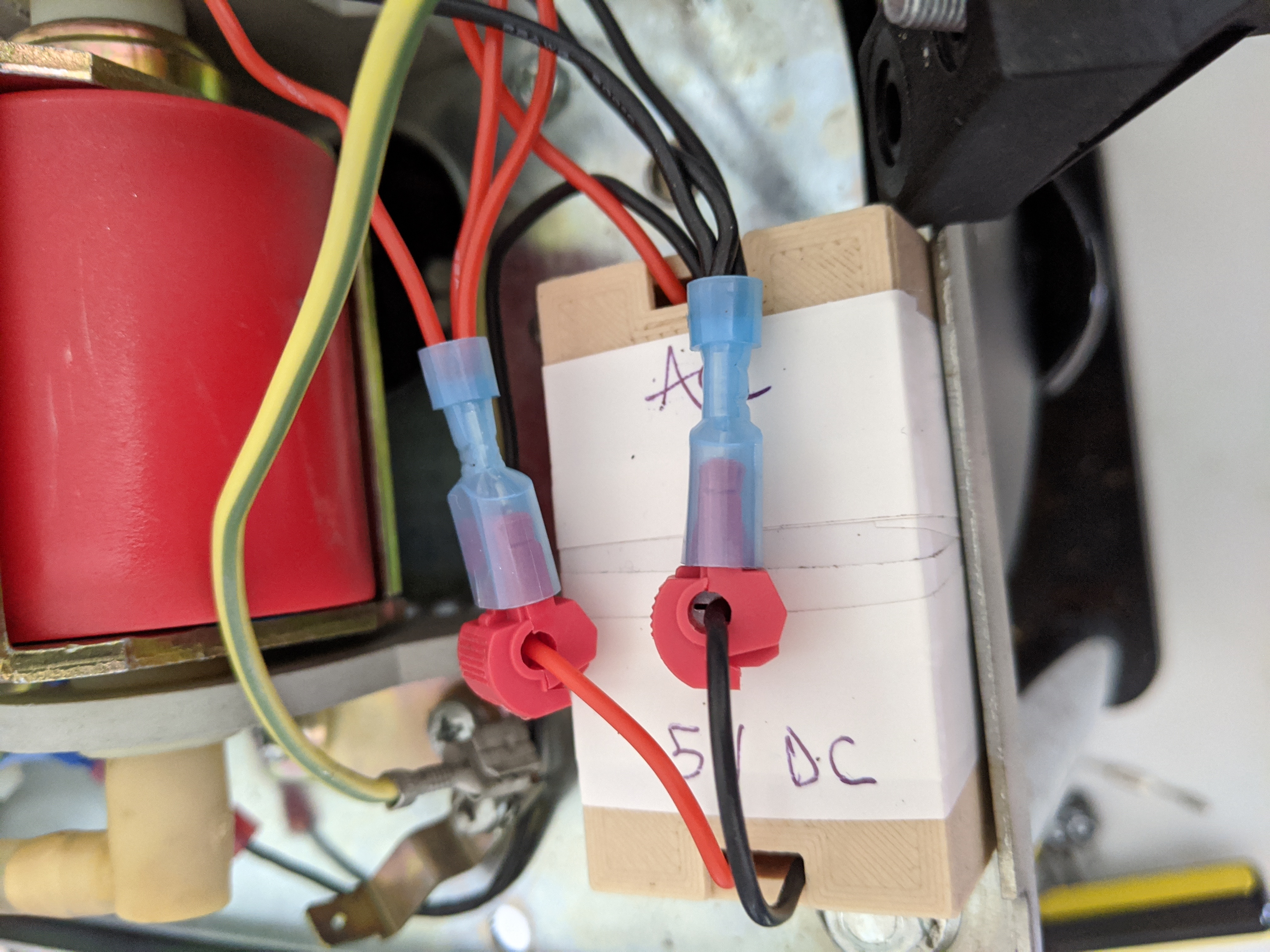

I also used two clamp wire connectors for the 5V and GND bus, again this makes

it easier and faster to assemble everything and swap components if required.

Clamp wire connectors for 5V and GND

6. Display

There is not a constraint on what display you can use, in my case I chose an OLED 128x64.

This display uses the SSD1306 controller and you can find several Arduino libraries

that let you interface with it.

The main reason to choose this type of display was that it uses the I2C protocol so I

only needed 2 Arduino pins to control it (plus 2 to power it up).

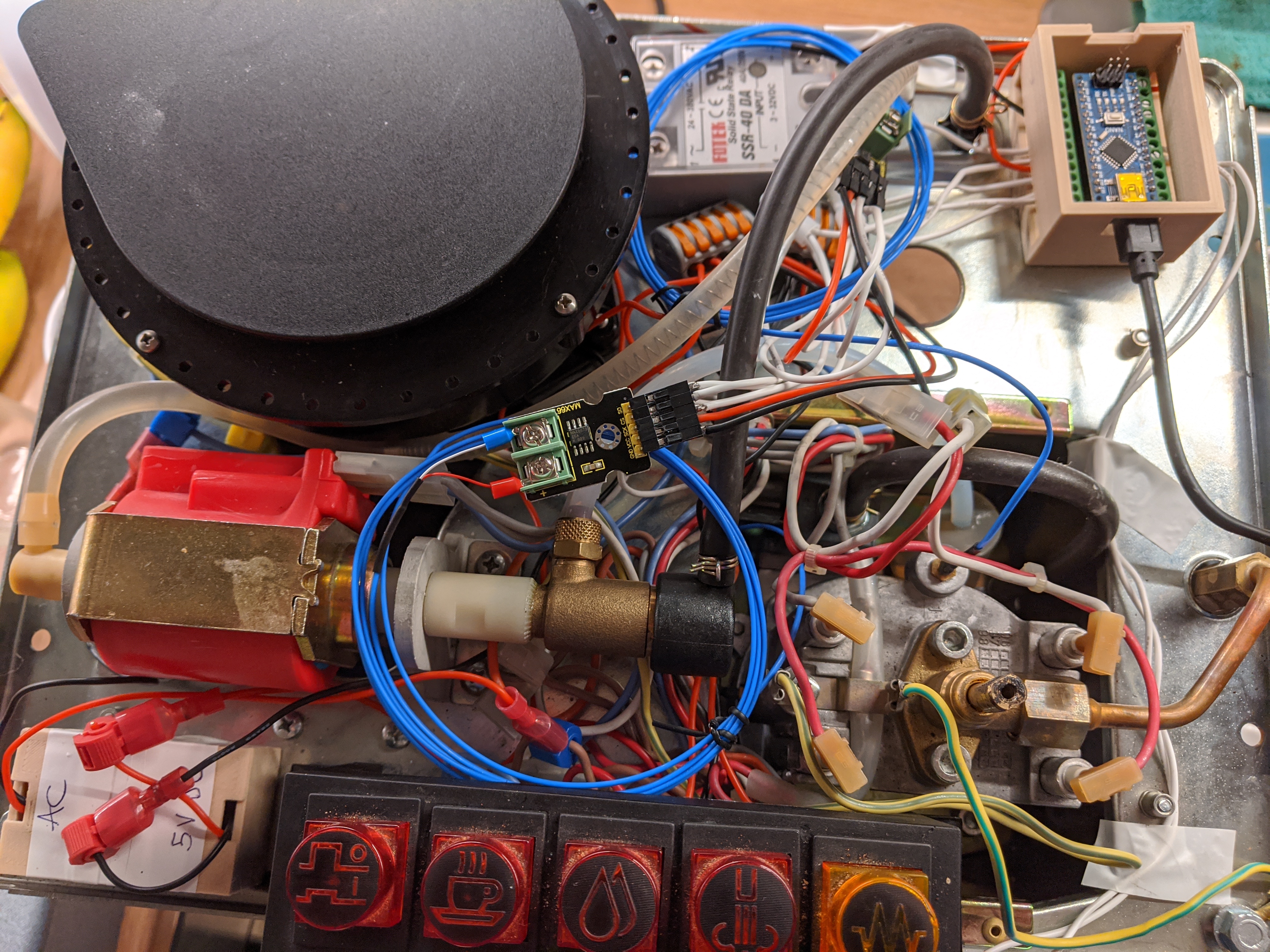

8. Assembly

In this section I’ll recap the steps I took from the beginning, until the final assembly with the PID controller installed in the coffee machine.

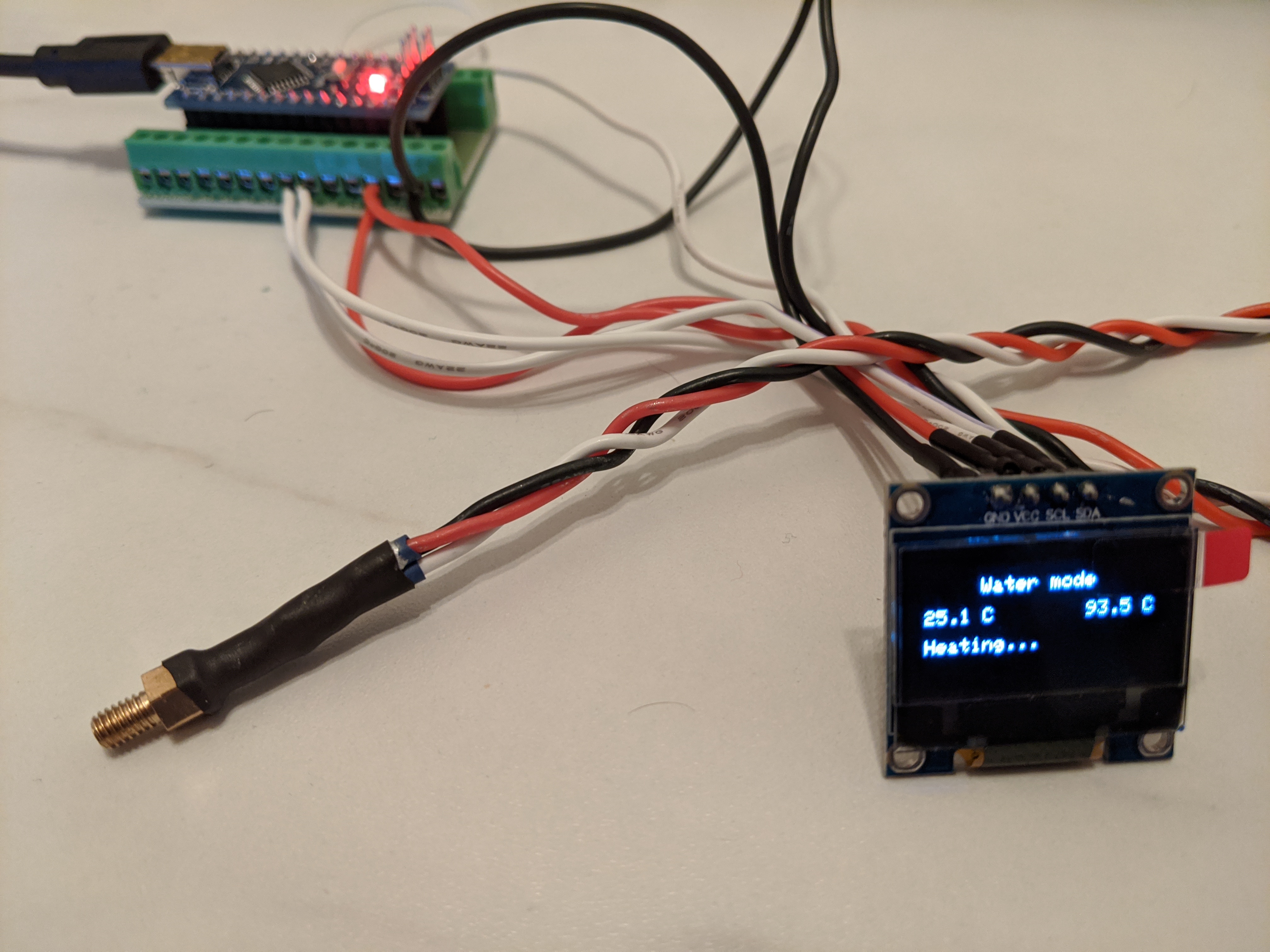

Once gathered all the materials for initial testing I wired everything on a breadboard to verify that the code was working as expected:

Testbench assembly

This also helped me to find a good starting point for the PID gains, at least better than

leaving them set to 1. They have been tuned again once everything was connected to the

machine heater.

First I applied two T-Tap connectors to the main AC power line. one can be applied to the Neutral just after the input socket, but it’s important to connect the second one after the main power button. This allows the Arduino to turn on only when the machine is on.

The AC-DC converter can be placed into it’s plastic container and the AC terminals can be connected to the two T-Tap connectors. The 5V output is going to be connected to the Arduino, the sensors and the display.

I then assembled the temperature sensors by unscrewing the thermostats and replacing them with the two sensors. For the water sensor, the heater must be freed removing its 4 screws that keeps it connected to the main group.

I placed the Arduino Nano with the expansion board and a plastic enclosure in the only

available space on the machine frame and I wired the 5V into the Vin pin, the GND

and the temperature sensors signal wires.

I then positioned the SSR near the coffee grinder, connecting it’s DC terminals to GND

and to the Arduino pin, for the AC terminals instead I used 18 AWG wire with male

spade connectors, that have been connected as described in Solid State Relay.

I removed the two connectors from the steam mode button which where used to short circuit

one of the thermostat. I used two T-Tap connectors as “female” spade connectors and I

wired them to GND and the Arduino pin.

Regarding the display, I decided to place it on the front of the machine, between

the amin group and the grinder, where there is a small unused gap. I wired the I2C

signals from the Arduino to the front of the machine and together if 5V and GND

from the power supply, I placed everything at the front of the machine.

Eventually I checked I connected all the wires to the appropriate port in the Arduino expansion shield and then I placed the external enclosure on the coffee machine back.

This is how the Gaggia Paros looks like after the modification.

The inside:

Final internal assembly of the Gaggia Paros

And the outside:

Final external assembly of the Gaggia Paros

9. PID Tuning

The last step was improving the PID controller by tuning the gains in order to achieve the best possible control of the heater. There are several guides online that explain what each gain does and how to resolve specific issues, I am not expert so I won’t cover this part. My suggestion is to get a basic understanding of how a PID controller works and then just try changing the gain values to see the effect.

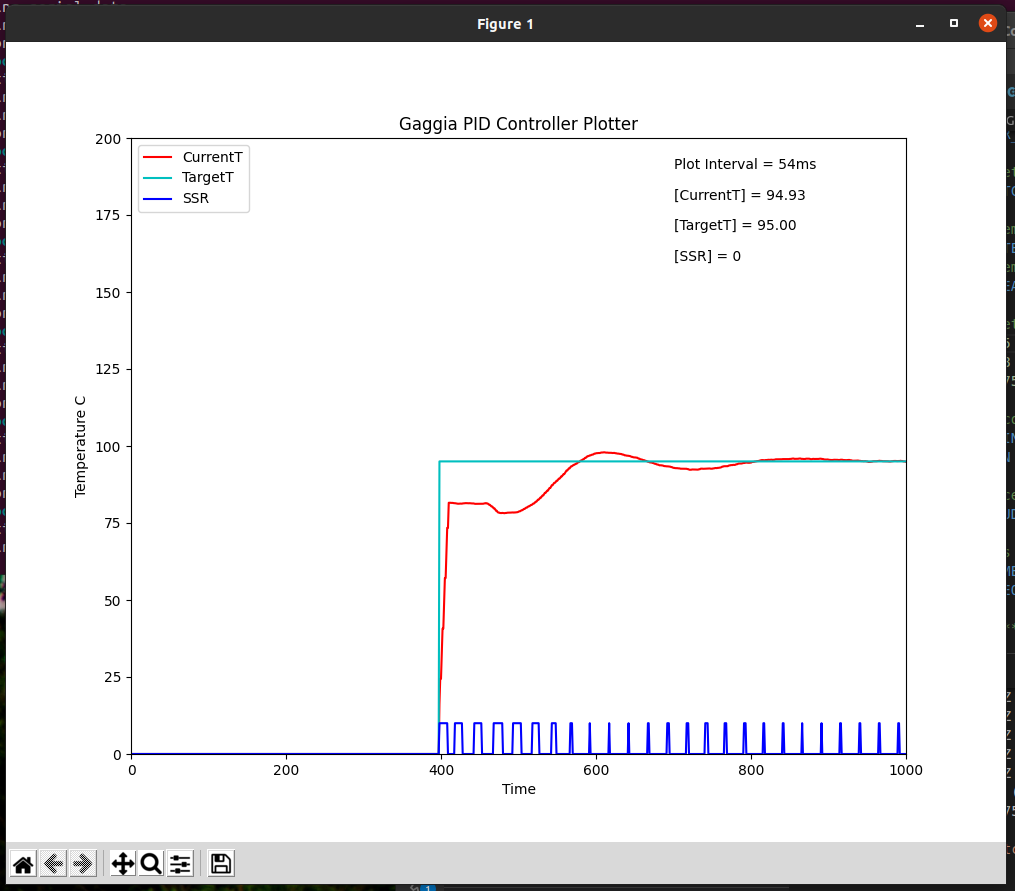

The Arduino code is configured by default to send the current machine status to the Serial

Interface in a comma separated string format.

In the repository tools directory there is a Python script that connects to

the machine serial port /dev/ttyUSB0 (a different port can be specified), reading

these messages coming from the Arduino and plotting the water temperature on a graph.

Having a real-time plot of the water temperature will help massively the PID tuning process, because you will clearly see the oscillations or the overshooting and it will be easier to correct them.

PID tuning temperature plot

10. Improvements

After a few months of use, everything still seems to be working as expected. The coffee quality has certainly improved and it’s more consistent than before, I really advise to apply such modification to any coffee machine!

There are still a few things that I’d like to improve:

Improve the internal wiring, I did not do a good job on that front

Replace the Arduino Nano with a ESP8266 based board to have WiFi connectivity

I hope these notes are useful to anybody attempting a similar modification and please submit Issues or PR on the GitHub repository.

Enjoy the coffee!